Here is a behind the scenes look at the process of getting the Santa Sack bags from my door to yours…

After a purchase is made I ship out all of the invoices and organize them with Excel for shipping purposes. I have found that being organized is the only way for things to run quickly and smoothly. I print my list out alphabetical by the buyers name and later when I print shipping labels I also arrange those alphabetical.

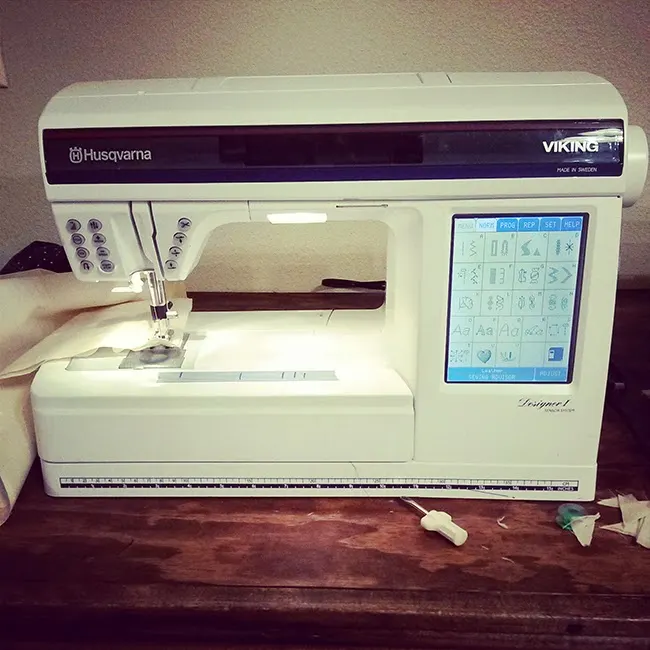

The next step is gathering all of the supplies … the fabric, ribbon and everything else I need (lots of thread, scissors, and even a lighter to seal the ends of each ribbon tie). After the supplies are gathered the fabric is cut to size and the ribbon is cut.

This is a picture from last year. My sister, her boyfriend and another friend were all at the desk helping a sista’ out! We work late and we drink lots of cocoa (and caffeine) to keep us going.

When the bags are sewn we run the ribbon through the tops to create the ribbon drawstring and use a lighter to heat seal the edges to prevent fraying. Some work even happens in my alternate office AKA swagger wagon AKA minivan while waiting in the school pick up line for my two oldest boys.

Once the bags are sewn it is ready to personalize them with the design. I designed the bags myself using Adobe Illustrator. I put in each name and align so everything is centered. Each design is cut into commercial grade vinyl, weeded and then pressed on a commercial heat press.

Enjoy,

I party HERE

I party HERE

Check out the Poofy Cheeks Blog Pinterest Board for other craft and recipe ideas!

Follow Poofy Cheeks’s board Poofy Cheeks Blog on Pinterest.

Garner

Wednesday 19th of August 2015

Nice Post!